RLSSP300 High Capacity Electric Submersible Sand Dredging Pump

1. Pumping tailing slurry for industrial and mining organizations;

2. Sucking silt in sedimentation basin;

3. Pumping silty sand or fine sand for seashore or port;

|

Model |

Water outlet (mm) |

Flow (m3/h) |

Head (m) |

Motor power (kW) |

Biggest particles discontinuous pass through (mm) |

|

RLSSP30 |

30 |

30 |

30 |

7.5 |

25 |

|

RLSSP50 |

50 |

25 |

30 |

5.5 |

18 |

|

|

50 |

40 |

22 |

7.5 |

25 |

|

RLSSP65 |

65 |

40 |

15 |

4 |

20 |

|

RLSSP70 |

70 |

70 |

12 |

5.5 |

25 |

|

RLSSP80 |

80 |

80 |

12 |

7.5 |

30 |

|

RLSSP100 |

100 |

100 |

25 |

15 |

30 |

|

|

100 |

200 |

12 |

18.5 |

37 |

|

RLSSP130 |

130 |

130 |

15 |

11 |

35 |

|

RLSSP150 |

150 |

100 |

35 |

30 |

21 |

|

|

150 |

150 |

45 |

55 |

21 |

|

|

150 |

200 |

50 |

75 |

14 |

|

RLSSP200 |

200 |

300 |

15 |

30 |

28 |

|

|

200 |

400 |

40 |

90 |

28 |

|

|

200 |

500 |

45 |

132 |

50 |

|

|

200 |

600 |

30 |

110 |

28 |

|

|

200 |

650 |

52 |

160 |

28 |

|

RLSSP250 |

250 |

600 |

15 |

55 |

46 |

|

RLSSP300 |

300 |

800 |

35 |

132 |

42 |

|

|

300 |

1000 |

40 |

200 |

42 |

|

RLSSP350 |

350 |

1500 |

35 |

250 |

50 |

|

RLSSP400 |

400 |

2000 |

35 |

315 |

60 |

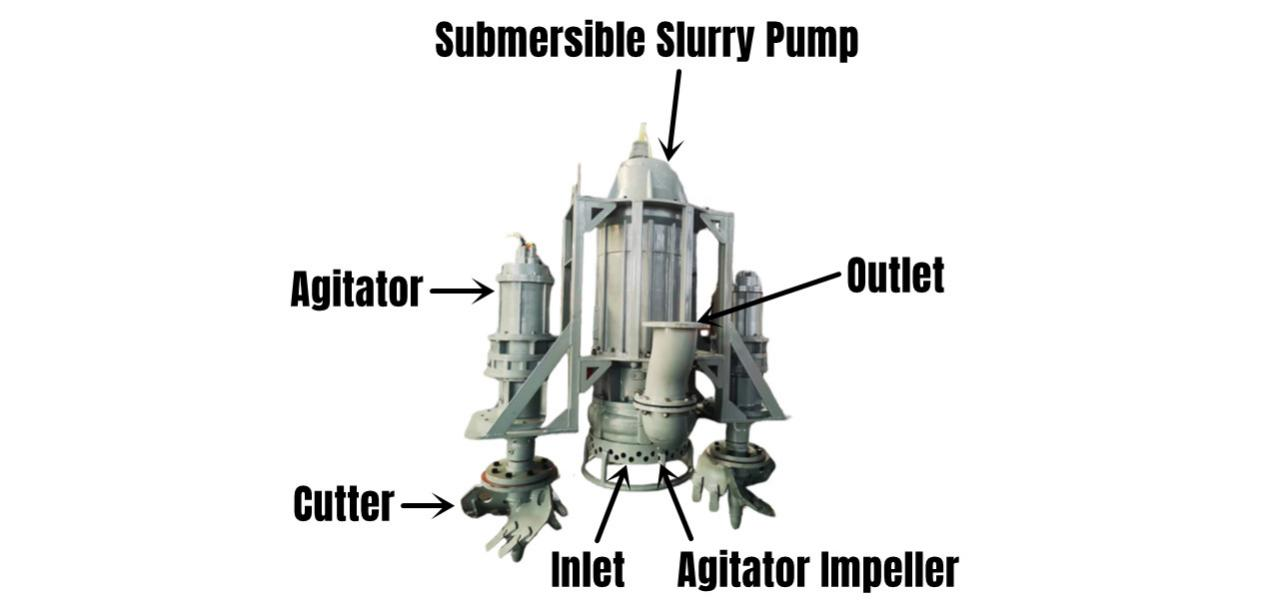

1. It is mainly composed of a motor, pump shell, impeller, guard plate, pump shaft, bearing seals, etc.

2. Unique mechanical seal device to protect the motor from high-pressure water and impurities, ensuring high suction efficiency.

3. In addition to the main impeller, two or three agitators can be added to the main pump body to help break and mix sludge, and improve the suction concentration of the slurry pump.

4. It is not required to build complicated ground protection and fixing device when the motor is inserted underwater, which is simple and convenient.

1. Normally 380V / 50Hz, three-phase AC power supply. Also can be customized 50Hz or 60Hz / 230V, 415V, 660V, 1140V three-phase AC power supply, distribution transformer capacity is 2-3 times the rated capacity of the motor. (Indicate power supply condition when ordering)

2. The working position in the medium is vertical upper suspension positioning, which can also be coupled with installation, the working state is continuous.

3. Diving depth of the unit: no more than 50m, the minimum diving depth shall be subject to the submerged motor.

4. Maximum concentration of solid particles in the medium: ash slag is 45%, slag is 60%.

5. Medium temperature shall not exceed 60℃, R type (high-temperature resistance) shall not exceed 140℃, without flammable and explosive gases.