RLSSP150 High Standard Electric Driven Submersible Dredge Pump

1. Pumping tailing slurry for industrial and mining organizations;

2. Sucking silt in sedimentation basin;

3. Pumping silty sand or fine sand for seashore or port;

4. Pumping powdery iron ore;

5. Deliver solid particles of mud, larger pulp, coal slurry, and sandstone;

6. Sucking from all kinds of the fly ash power plants, coal slime

|

Model |

Water outlet (mm) |

Flow (m3/h) |

Head (m) |

Motor power (kW) |

Biggest particles discontinuous pass through (mm) |

|

RLSSP30 |

30 |

30 |

30 |

7.5 |

25 |

|

RLSSP50 |

50 |

25 |

30 |

5.5 |

18 |

|

|

50 |

40 |

22 |

7.5 |

25 |

|

RLSSP65 |

65 |

40 |

15 |

4 |

20 |

|

RLSSP70 |

70 |

70 |

12 |

5.5 |

25 |

|

RLSSP80 |

80 |

80 |

12 |

7.5 |

30 |

|

RLSSP100 |

100 |

100 |

25 |

15 |

30 |

|

|

100 |

200 |

12 |

18.5 |

37 |

|

RLSSP130 |

130 |

130 |

15 |

11 |

35 |

|

RLSSP150 |

150 |

100 |

35 |

30 |

21 |

|

|

150 |

150 |

45 |

55 |

21 |

|

|

150 |

200 |

50 |

75 |

14 |

|

RLSSP200 |

200 |

300 |

15 |

30 |

28 |

|

|

200 |

400 |

40 |

90 |

28 |

|

|

200 |

500 |

45 |

132 |

50 |

|

|

200 |

600 |

30 |

110 |

28 |

|

|

200 |

650 |

52 |

160 |

28 |

|

RLSSP250 |

250 |

600 |

15 |

55 |

46 |

|

RLSSP300 |

300 |

800 |

35 |

132 |

42 |

|

|

300 |

1000 |

40 |

200 |

42 |

|

RLSSP350 |

350 |

1500 |

35 |

250 |

50 |

|

RLSSP400 |

400 |

2000 |

35 |

315 |

60 |

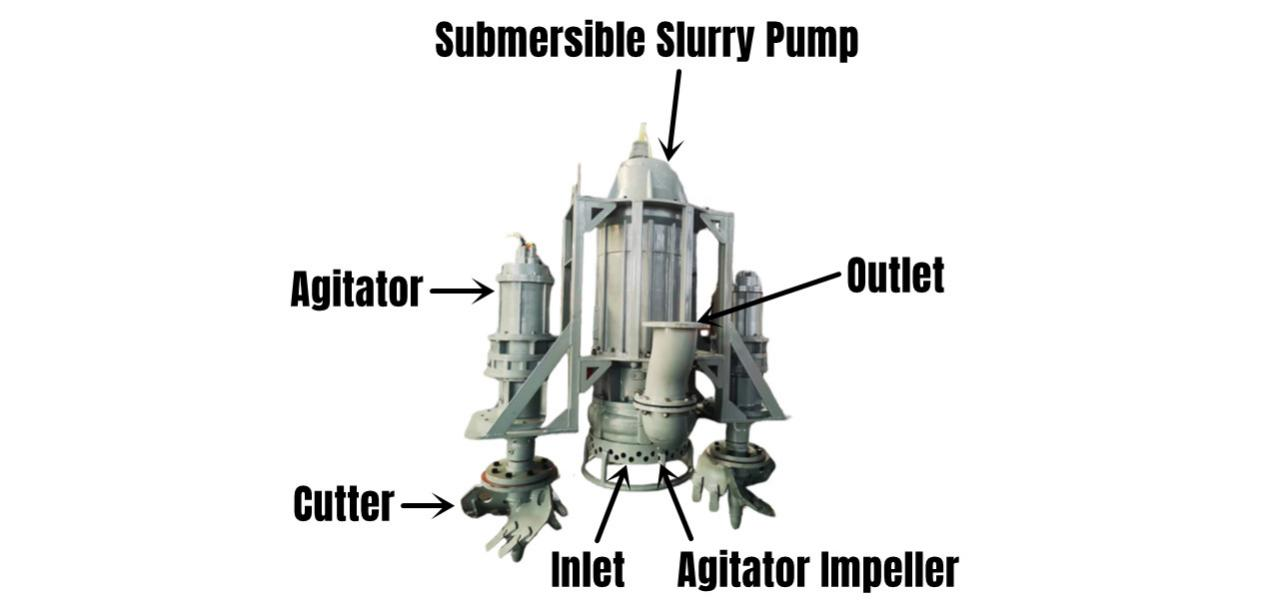

1. It is mainly composed of a motor, pump shell, impeller, guard plate, pump shaft, bearing seals, etc.

2. The main parts of the submersible mud pump are made of wear-resistant material - chromium alloy, which has better stability and longer service life.

3. The whole machine is dry pump type, the motor adopts oil chamber sealing mode, equipped with three sets of hard alloy mechanical seal, which can effectively prevent high-pressure water and impurities into the motor cavity.

4. In addition to the main impeller, two or three agitators can be added to the main pump body to help break and mix sludge, and improve the suction concentration of the slurry pump.

5. The impeller is in direct contact with the deposition surface, and the concentration is controlled by diving depth. In addition, the auxiliary reamer can be added to increase the concentration of medium extraction because of the high hardness and compaction of medium precipitation.

6. It is not required to build complicated ground protection and fixing device when the motor is inserted underwater, which is simple and convenient.