OEM/ODM Factory Dragflow Hydraulic Pump - Heavy Duty Industrial Dredging Mineral Centrifugal Slurry Pump – Relong

OEM/ODM Factory Dragflow Hydraulic Pump - Heavy Duty Industrial Dredging Mineral Centrifugal Slurry Pump – Relong Detail:

Design Features

Power End

✔ Labyrinth bearing isolators to protect internal components during wash-down cycles.

✔ Clearances can be easily adjusted to maintain efficiency while optimizing performance and extending wear life.

✔ Over-sized, self-aligning spherical roller bearings for trouble free operation.

✔ Heavy duty bearing assembly, 50,000 hour minimum L10 bearing life, Distortion free bearing clamp system ensures maximum bearing life and prevents premature fatigue.

Wet End

✔ Maintenance friendly split casing for elastomer liners (lined wet end).

✔ Static vanes reduce wear and prevent erosion.

✔ Tangential discharge improves efficiency and reduces wear.

✔ Optimized hydraulics for high efficiency and low wear.

✔ Dowel pins for easy and accurate split case alignment (lined wet end).

✔ Ribs designed for optimized strength/weight.

✔ Static suction vanes extend wear life (metal wet end).

✔ Patented flange system for ease of maintenance (metal wet end).

✔ Adjustable suction cover on sizes 200 and larger to optimize efficiency and minimize wear.

Sealing arrangements

✔ Packed gland with expeller configuration (other sealing options available).

✔ Split stuffing box for simplified installation and adjustments.

✔ Mating shaft sleeves with engineered materials for extended life.

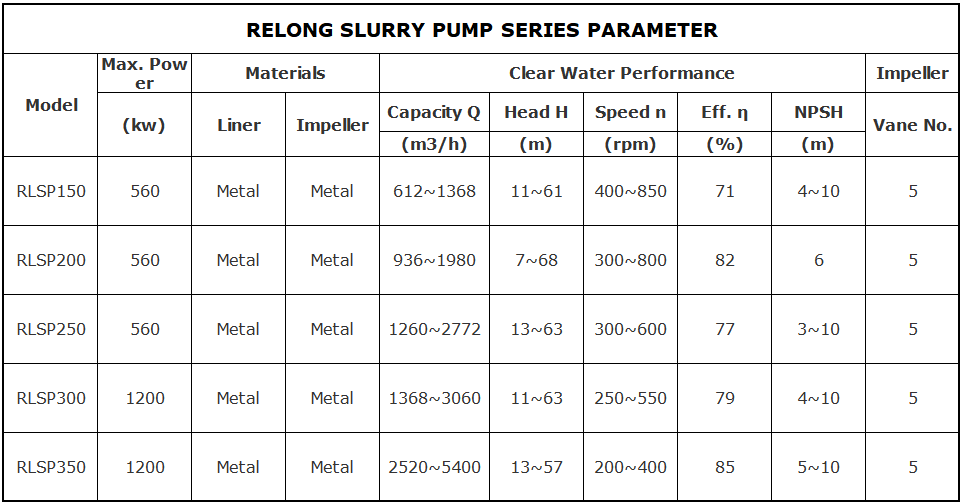

Performance Parameters

Applications

The Slurry Pumps are widely used to transport high-hardness, strong-corrosion and high-concentration liquids that contain suspended solid particles, such as finished ores, refuse ores, ashes, cinders, cements, mud, mineral stones, lime and etc. in the industries of metallurgy, mining, coal, power, building material and etc. The temperature of the pumped solid-liquid mixture should be ≤80℃, and the weight concentration should be ≤60.

Product detail pictures:

Related Product Guide:

We now have many fantastic staff members customers superior at advertising, QC, and working with varieties of troublesome problem within the generation system for OEM/ODM Factory Dragflow Hydraulic Pump - Heavy Duty Industrial Dredging Mineral Centrifugal Slurry Pump – Relong , The product will supply to all over the world, such as: Turin, Myanmar, Puerto Rico, Our faith is to be honest first, so we just supply high quality products to our customers. Really hope that we can be business partners. We believe that we can establish long time business relationship with each other. You can contact us freely for more information and pricelist of our products !

Good quality and fast delivery, it's very nice. Some products have a little bit problem, but the supplier replaced timely, overall, we are satisfied.