The flange chassis of a flange crane has several advantages in its structure, contributing to improved performance and versatility. Here are some advantages of the flange chassis of a flange marine crane:

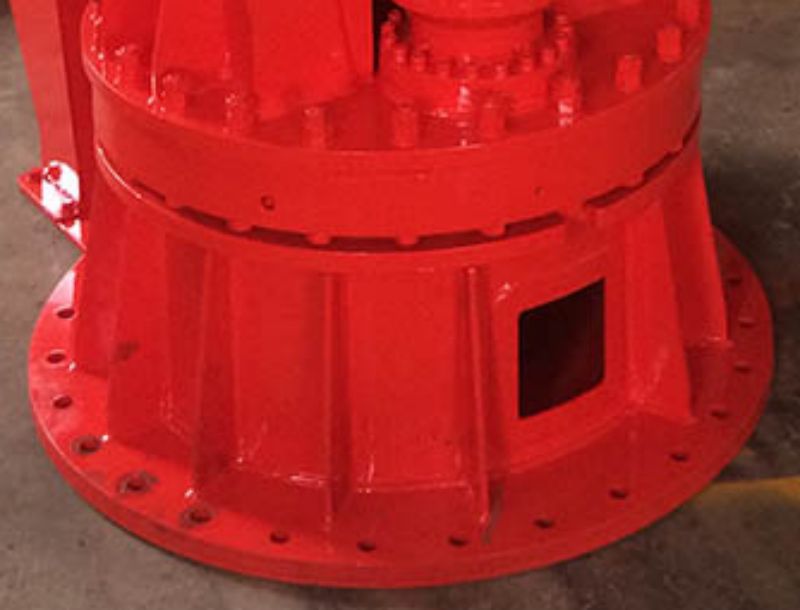

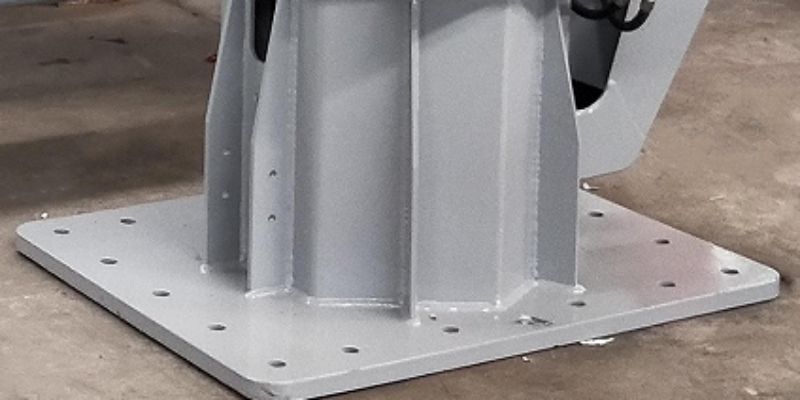

Stability and Support: The flange chassis is typically designed as a robust and stable foundation to support the structure and lifting operations of the knuckle boom marine crane and telescopic boom marine crane. It provides the necessary stability to ensure the crane remains balanced during lifting heavy loads.

Center of Gravity Control: The design of the flange chassis helps control the crane‘s center of gravity, enhancing stability during lifting and movement. This is crucial when handling large-capacity loads.

Adaptability: Flange chassis can be customized based on the type and application of the lifting equipment. This includes adjustments for lifting height, base size, and shape, among other factors. Consequently, they can adapt to various working scenarios.

Safety: The stability and support provided by the flange chassis contribute to improved operational safety. They can minimize the risk of tipping over or falling, ensuring the safety of operators and nearby personnel.

Corrosion Resistance and Durability: Flange chassis are typically constructed using corrosion-resistant materials and coatings, enhancing their durability, especially in harsh working environments.

Ease of Maintenance: The structure of flange chassis is often designed for ease of maintenance and cleaning, ensuring long-term performance.

In summary, the flange chassis of a knuckle boom flange crane and telescopic boom flange crane offers advantages such as stability, support, center of gravity control, safety, adaptability, mobility, corrosion resistance, and ease of maintenance. These features make it a reliable and efficient tool for various lifting tasks. Different models and applications of flange cranes may have different flange chassis designs tailored to specific needs.

Post time: Oct-10-2023