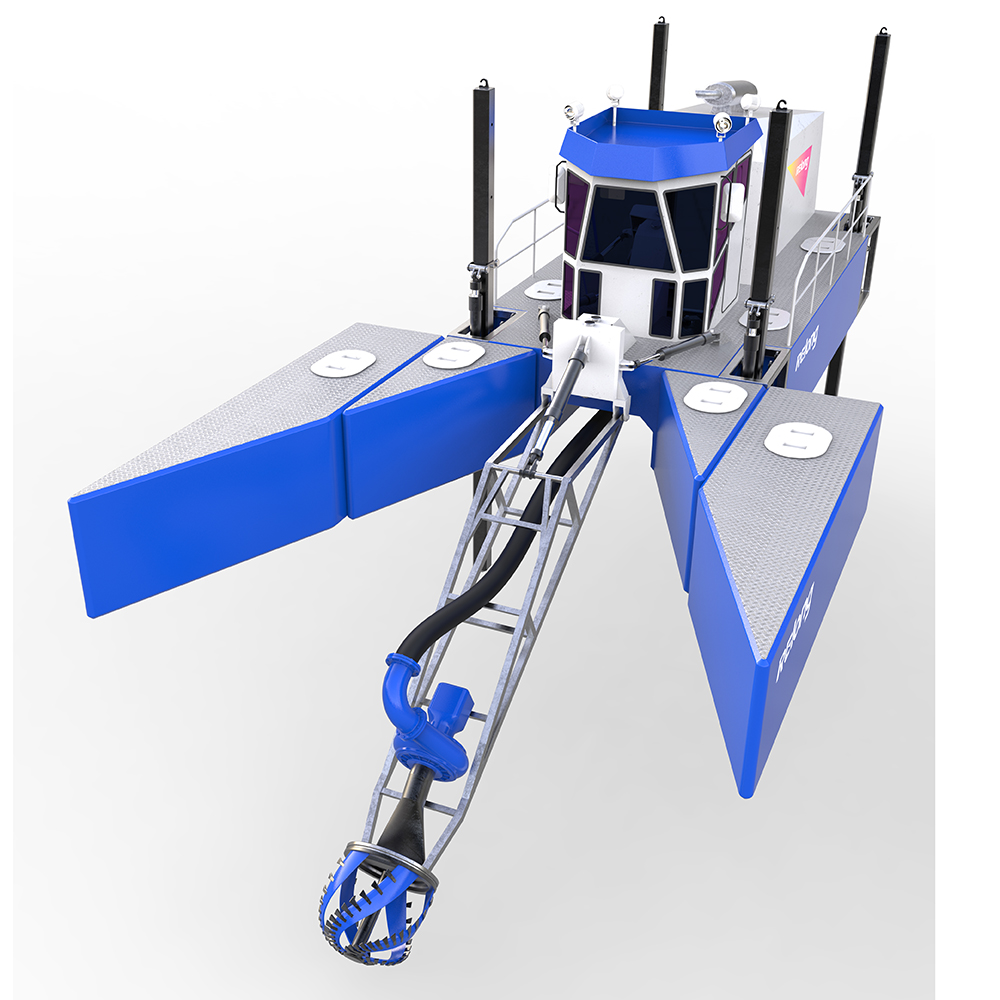

Good User Reputation for Heavy Duty Slurry Pump - Relong Hydarulic slurry dredge pump with agitors – Relong

Good User Reputation for Heavy Duty Slurry Pump - Relong Hydarulic slurry dredge pump with agitors – Relong Detail:

Application

Mainly as accessory device of excavator, in water, mud, mud, sand thin for mining under the condition of vehicle transportation, and the inconv-enience in the hydraulic mud pump pumping operations, greatly improve the working efficiency, is widely used in inland river channel

dredging project, harbor sediment governance, tailings sand, ore dressing, such as municipal sewage discharge deposition, etc.

Working Principle

The hydraulic system provides the power, the motor as the executive component, the hydraulic energy into mechanical energy of the new sand pump. At work, the energy is transferred to the slurry medium through the pump to stir the impeller rotation, so that it produces a certain flow rate, drives the solid flow, and realizes the slurry transportation.

The hydraulic motor adopts domestic famous quantitative piston motor and five star motor, which has the characteristics of advanced and reasonable structure, good performance, high efficiency and stable work. According to the actual working conditions of customers, choose different displacement motors.

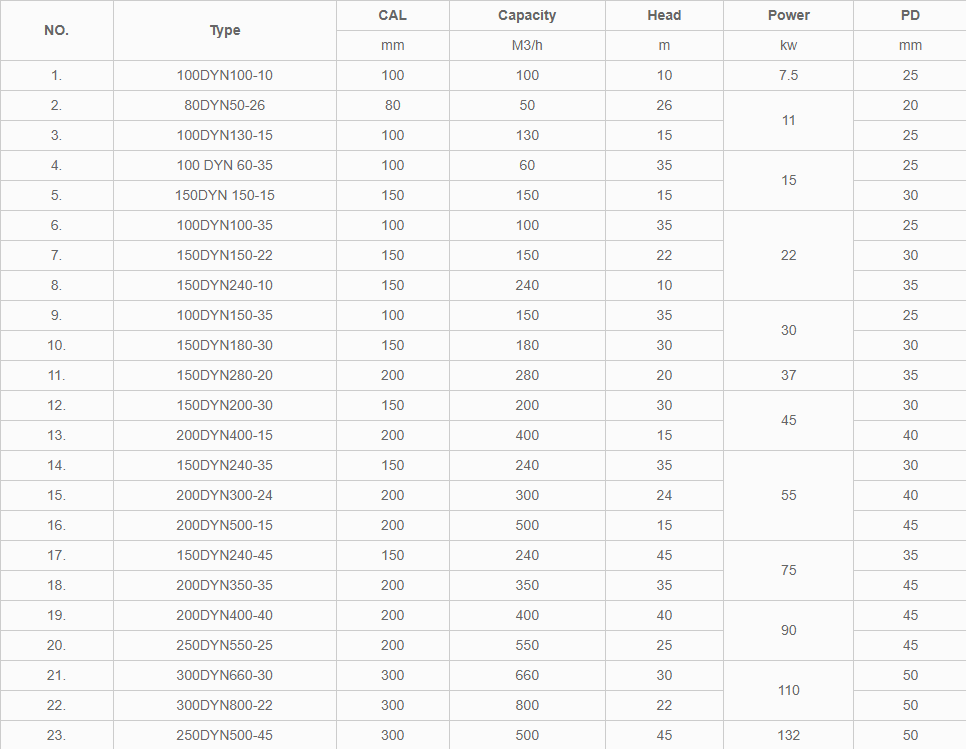

Spectifications

Main Features

1, the bottom of the pump with stirring impeller, and can be equipped with both sides of the reamer or cage, loosening the stiff sediment, improve the extraction concentration, automatic hinging, but also to prevent large solid material will pump plugging, so that solid and liquid fully mixed, so as to facilitate processing.

2, the pump can handle the maximum particle size of 50mm solid material, solid-liquid extraction concentration can reach more than 70%;

Note: Due to different operating conditions, pump output may vary depending on the processing medium, field operation, conveying distance and other factors.

3, the device is mainly installed on the excavator, the power is provided by the hydraulic station of the excavator, can realize free transfer, and the power source is diesel engine, in remote areas of construction can solve the problem of inconvenient electricity.

4, flow parts: that is, pump shell, impeller, guard plate, mixing impeller are made of high chromium alloy, can also be customized with other materials.

5, the use of unique sealing device, avoid frequent replacement of machine seal, improve work efficiency.

Product Advantages

Compared with the electric submersible cement sand pump, it has the following advantages:

1, hydraulic transmission movement inertia is small, fast reaction speed, can achieve a wide range of stepless speed regulation;

2, automatic overload protection, no motor burning phenomenon;

3, the extraction of sand slurry, sediment, slag and other solid concentration is high, can reach more than 70%;

4, connected to excavators and other machines with hydraulic system, can realize free transition, especially in remote areas of construction, power shortage, the advantage is more obvious;

5, can be used as an accessory of the excavator, in the adverse digging when extraction and long-distance transportation, improve the value of the excavator itself.

Product detail pictures:

Related Product Guide:

Control the standard by the details, show the power by quality. Our firm has strived to establish a extremely efficient and stable employees crew and explored an effective excellent command method for Good User Reputation for Heavy Duty Slurry Pump - Relong Hydarulic slurry dredge pump with agitors – Relong , The product will supply to all over the world, such as: Cape Town, Pakistan, Los Angeles, The company attaches great importance to product quality and service quality, based on the business philosophy good with people, genuine to whole world, your satisfaction is our pursuit. we design products, According to customer's sample and requirements, to meet the needs of the market and offer different customers with personalized service. Our company warmly welcomes friends at home and abroad to visit, to discuss cooperation and seek common development!

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!