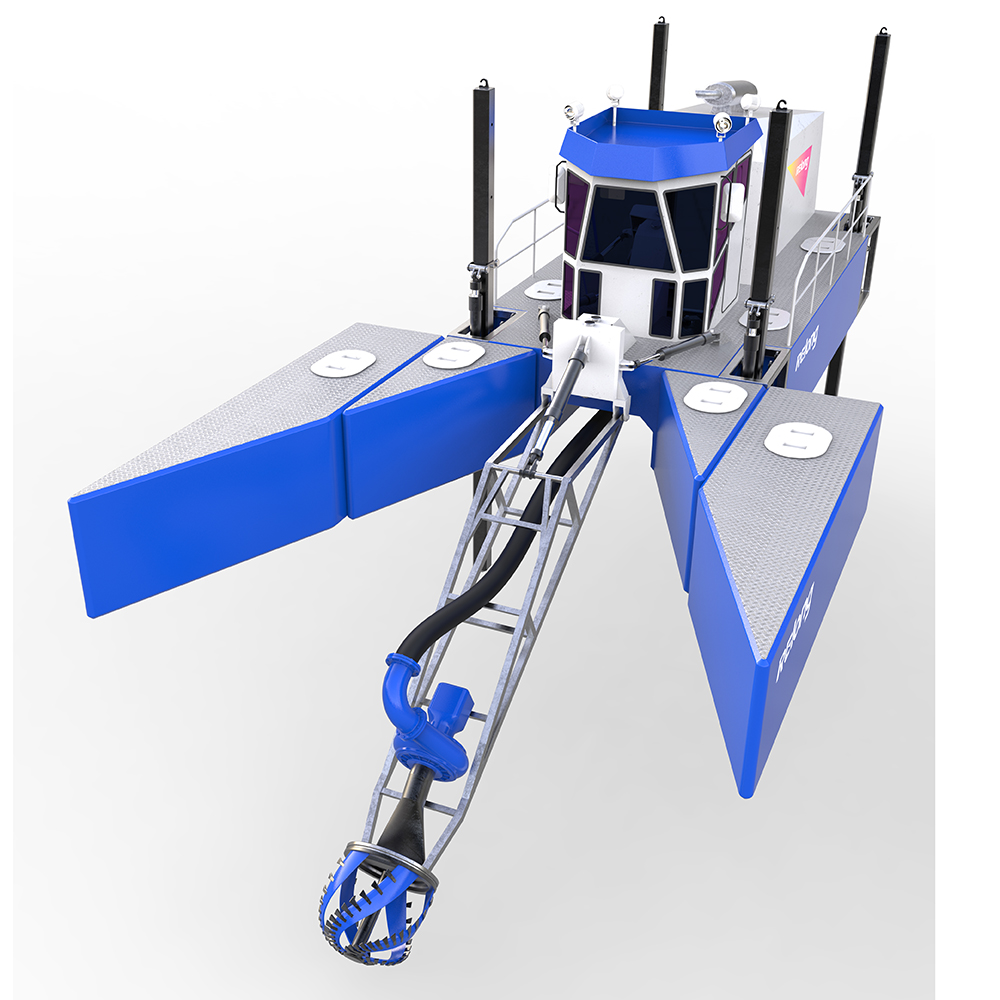

2021 Latest Design Cement Slurry Pump - RLSSP150 High Standard Electric Driven Submersible Dredge Pump – Relong

2021 Latest Design Cement Slurry Pump - RLSSP150 High Standard Electric Driven Submersible Dredge Pump – Relong Detail:

Application:

1. Pumping tailing slurry for industrial and mining organizations;

2. Sucking silt in sedimentation basin;

3. Pumping silty sand or fine sand for seashore or port;

4. Pumping powdery iron ore;

5. Deliver solid particles of mud, larger pulp, coal slurry, and sandstone;

6. Sucking from all kinds of the fly ash power plants, coal slime

Specification

|

Model |

Water outlet (mm) |

Flow (m3/h) |

Head (m) |

Motor power (kW) |

Biggest particles discontinuous pass through (mm) |

|

RLSSP30 |

30 |

30 |

30 |

7.5 |

25 |

|

RLSSP50 |

50 |

25 |

30 |

5.5 |

18 |

|

|

50 |

40 |

22 |

7.5 |

25 |

|

RLSSP65 |

65 |

40 |

15 |

4 |

20 |

|

RLSSP70 |

70 |

70 |

12 |

5.5 |

25 |

|

RLSSP80 |

80 |

80 |

12 |

7.5 |

30 |

|

RLSSP100 |

100 |

100 |

25 |

15 |

30 |

|

|

100 |

200 |

12 |

18.5 |

37 |

|

RLSSP130 |

130 |

130 |

15 |

11 |

35 |

|

RLSSP150 |

150 |

100 |

35 |

30 |

21 |

|

|

150 |

150 |

45 |

55 |

21 |

|

|

150 |

200 |

50 |

75 |

14 |

|

RLSSP200 |

200 |

300 |

15 |

30 |

28 |

|

|

200 |

400 |

40 |

90 |

28 |

|

|

200 |

500 |

45 |

132 |

50 |

|

|

200 |

600 |

30 |

110 |

28 |

|

|

200 |

650 |

52 |

160 |

28 |

|

RLSSP250 |

250 |

600 |

15 |

55 |

46 |

|

RLSSP300 |

300 |

800 |

35 |

132 |

42 |

|

|

300 |

1000 |

40 |

200 |

42 |

|

RLSSP350 |

350 |

1500 |

35 |

250 |

50 |

|

RLSSP400 |

400 |

2000 |

35 |

315 |

60 |

Product Features

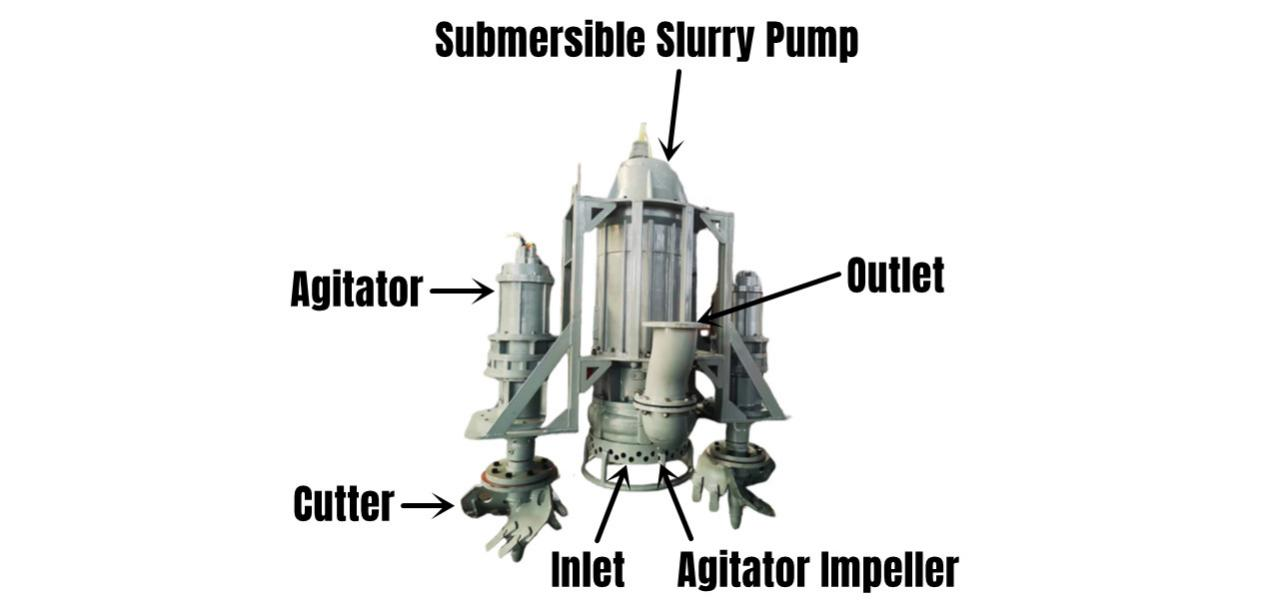

1. It is mainly composed of a motor, pump shell, impeller, guard plate, pump shaft, bearing seals, etc.

2. The material of the pump shell, impeller, and guard plate is made of high chromium alloy wear-resisting material, which has strong wear-resisting, corrosion-resisting, and sand-discharging ability and can pass through large solid particles.

3. The whole machine is dry pump type, the motor adopts oil chamber sealing mode, equipped with three sets of hard alloy mechanical seal, which can effectively prevent high-pressure water and impurities into the motor cavity.

4. In addition to the main impeller, there is also a stirring impeller, which can precipitate the sludge on the bottom of the water into turbulence after extraction.

5. The impeller is in direct contact with the deposition surface, and the concentration is controlled by diving depth. In addition, the auxiliary reamer can be added to increase the concentration of medium extraction because of the high hardness and compaction of medium precipitation.

6. Not limited by suction range, high slag absorption efficiency, and more thorough silt removal.

7. The equipment works directly underwater, without noise and vibration, making the site cleaner.

Working Conditions

1. Normally 380V / 50Hz, three-phase AC power supply. Also can be customized 50Hz or 60Hz / 230V, 415V, 660V, 1140V three-phase AC power supply, distribution transformer capacity is 2-3 times the rated capacity of the motor. (Indicate power supply condition when ordering)

2. The working position in the medium is vertical upper suspension positioning, which can also be coupled with installation, the working state is continuous.

3. Diving depth of the unit: no more than 50m, the minimum diving depth shall be subject to the submerged motor.

4. Maximum concentration of solid particles in the medium: ash slag is 45%, slag is 60%.

5. Medium temperature shall not exceed 60℃, R type (high-temperature resistance) shall not exceed 140℃, without flammable and explosive gases.

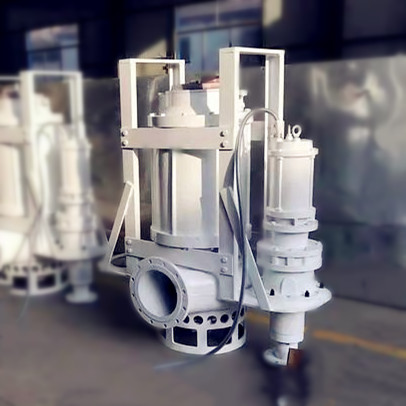

Product detail pictures:

Related Product Guide:

We aim to find out high quality disfigurement in the generation and provide the most effective services to domestic and abroad clients wholeheartedly for 2021 Latest Design Cement Slurry Pump - RLSSP150 High Standard Electric Driven Submersible Dredge Pump – Relong , The product will supply to all over the world, such as: Italy, Mongolia, Stuttgart, We believe in establishing healthy customer relationships and positive interaction for business. Close cooperation with our customers has helped us to create strong supply chains and reap benefits. Our products have gained us widespread acceptance and the satisfaction of our worldwide valued clients.

It can be said that this is a best producer we encountered in China in this industry, we feel lucky to work with so excellent manufacturer.